Porcelain pavers have gained immense popularity in recent years due to their durability, aesthetic appeal, and versatility. However, their dense composition also presents a challenge when it comes to cutting them to fit specific dimensions or shapes. So how to cut porcelain pavers?

In this article, we will provide you with a detailed tutorial on how to cut porcelain pavers, including the necessary tools, techniques, and essential tips to achieve precise and clean cuts.

For a full guide on porcelain pavers, including their pros and cons, click here.

Jump to:

How to cut porcelain pavers: safety precautions

Before we even begin talking about how to cut porcelain pavers, there are some extremely important safety precautions we need to consider.

First of all, you need to get in contact with local authorities to know what are the rules when it comes to dust exposure in your area. In some places, there’s legislation that forbids the dry cutting of masonry materials.

This is because, when cutting masonry products, fine particles of silica dust are dispersed in the air. This is extremely prejudicial to your health.

So we highly recommend the use of wet cutting techniques (we will explain in detail what exactly that is ahead).

New Jersey law, for example, forbids dry-cutting masonry. The United States Department of Labor also has laws in place to protect its workers.

Knowing that, there are also the basic security measures of wearing safety goggles and gloves to protect your eyes and hands from flying debris. Ear protection is also important when operating power tools such as wet saws or angle grinders.

Make sure to work in a well-ventilated area or wear a dust mask to prevent inhalation of dust particles, and always follow the manufacturer’s instructions for operating the tools and equipment safely.

In addition to safety goggles and gloves, it’s important to wear appropriate clothing that covers your arms and legs. This helps protect your skin from potential cuts or abrasions and provides an extra layer of safety.

Use sturdy, closed-toe shoes or boots with slip-resistant soles to prevent accidental slips or falls. Avoid wearing sandals or open-toe shoes that may expose your feet to potential hazards.

Clear the work area of any potential tripping hazards, debris, or clutter. Make sure the surrounding space is well-lit and free from obstructions. Consider using barriers or warning signs to prevent others from entering the work zone.

Be cautious of cords and cables. Inspect them regularly for any signs of damage, and never operate tools with frayed or exposed wires. Use ground fault circuit interrupters (GFCIs) when working in wet environments to minimize the risk of electric shocks.

Techniques for cutting porcelain pavers

We are going to talk about the four main methods to cut porcelain pavers: wet saw, angle grinder, manual scoring-snapping, and circular saw.

Wet saw

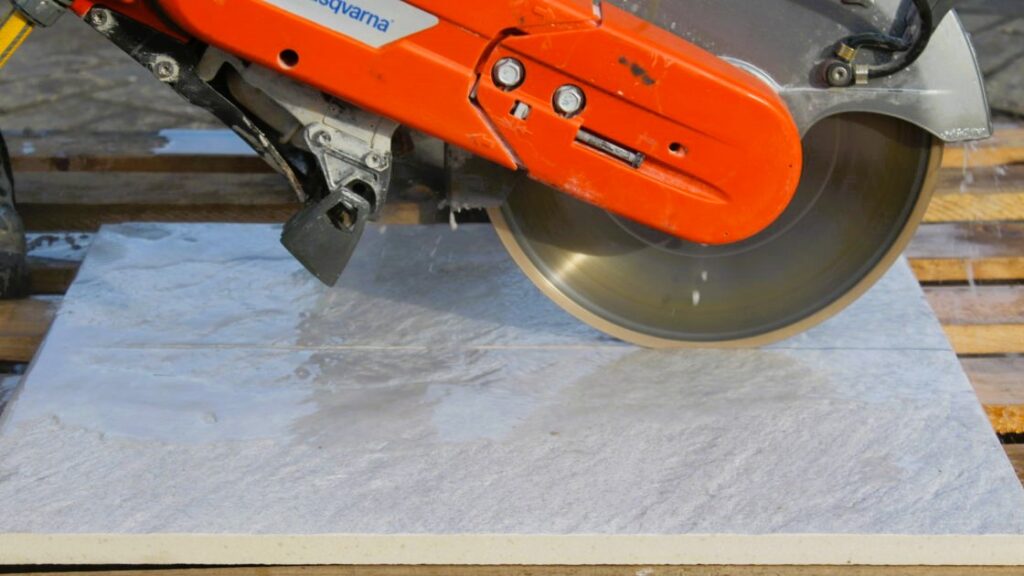

The wet saw is the most commonly used tool for cutting porcelain pavers due to its effectiveness and precision.

Preparation

Before starting, ensure you have a suitable wet saw for cutting porcelain pavers. Read and understand the manufacturer’s instructions for your specific wet saw model. Fill the wet saw’s reservoir with water as directed by the manufacturer.

This reservoir supplies water to the blade during the cutting process, reducing friction and keeping the blade and material cool. It also prevents the formation of dust, in pair with what we mentioned before.

Take note of the thickness of the porcelain paver and adjust the blade’s depth on the wet saw accordingly. Most wet saws have a knob or lever that allows you to adjust the depth. Set the blade depth so that it extends just below the surface of the paver, ensuring a clean and precise cut.

Adjust the blade angle if necessary. Some wet saws have a tilting mechanism that allows you to cut at different angles. Align the blade angle with the desired cut angle if you need to make bevel cuts or angled edges.

Place the porcelain paver on the cutting table of the wet saw, ensuring that it is securely positioned. If needed, use clamps or other appropriate methods to hold the paver in place. Take into account the cut line you want to make and position the paver accordingly.

Cutting the porcelain paver

Make sure the cut line on the porcelain paver is aligned with the blade on the wet saw. Take your time to ensure accurate alignment, as this will determine the quality of the cut. Double-check that the paver is stable and won’t shift during the cutting process.

Switch on the wet saw, allowing the blade to reach its maximum speed before making contact with the porcelain paver. Slowly feed the paver into the blade, applying even pressure throughout the cutting process.

Avoid forcing the paver or pushing too quickly, as this may result in a rough or uneven cut. Instead, let the blade do the work while maintaining a steady pace.

The water in the wet saw’s reservoir is crucial for cooling the blade and preventing overheating. As you cut through the porcelain paver, the water will flow onto the blade, dissipating heat and keeping it within a suitable operating temperature.

Throughout the cutting process, pay attention to the water flow and ensure it is adequate. If necessary, adjust the water flow or add more water to the reservoir. Monitor the blade’s temperature and take breaks if it becomes too hot, allowing it to cool down before continuing.

Angle grinder

Not as powerful or reliable as the wet saw, the angle grinder is a versatile tool that can be used for smaller cuts or shaping the edges of porcelain pavers.

Preparation

Select a blade suitable for cutting porcelain pavers and attach it securely to the angle grinder. Some blades are specifically designed for cutting hard materials like porcelain and offer efficient and precise cutting.

Using a pencil or marker, mark the desired cut line on the surface of the porcelain paver. Take your time to ensure the line is accurate and aligns with your intended cut.

Place the porcelain paver on a stable surface, such as a workbench or sturdy sawhorse, ensuring it is well-supported and won’t move during the cutting process. Consider using clamps or other appropriate methods to hold the paver securely in place.

Wet cutting

Also, that is a process you cannot do alone. You are going to need help to keep the pavers you’re cutting wet, with either a spray bottle or a hose. Focus on the place you’re cutting, lightly misting the places where the blade contacts the paver as you go.

That’s what we call wet cutting. You’re basically simulating what a wet saw would do. But make no mistake about it, it’s a crucial step that you can’t skip.

Making the cut

Turn on the angle grinder and let the blade reach its maximum speed before making contact with the porcelain paver. Ensure you have a firm grip on the grinder and maintain control throughout the cutting process.

Position the blade of the angle grinder at the starting point of the marked cut line. Apply light pressure and carefully guide the blade along the line, allowing the diamond blade to cut through the porcelain. Keep a steady pace and avoid excessive force, as this may result in a rough or uneven cut.

To minimize heat buildup and potential damage to the porcelain paver, it’s recommended to make several shallow passes rather than cutting through the material in a single attempt.

This approach helps to dissipate heat and maintain better control over the cutting process. Take your time and focus on achieving a clean and accurate cut.

Manual scoring-snapping

The manual scoring-snapping method is an effective way to make straight cuts in porcelain pavers using a tile cutter with a scoring wheel. Although the density of porcelain pavers makes it harder, it can be a good solution when you need to cut only a few pavers.

Preparation

Using a pencil or marker, mark the desired cut line on the surface of the porcelain paver. Take your time to ensure the line is accurate and aligns with your intended cut.

Place the porcelain paver on a stable surface or the cutting table of the manual tile cutter, ensuring it is well-supported and won’t move during the cutting process. Consider using clamps or other appropriate methods to hold the paver securely in place.

Select a manual tile cutter specifically designed for cutting porcelain. These tile cutters typically consist of a base with a cutting table, a scoring wheel, and a handle for applying pressure. Ensure that the cutting table is smooth and clean, allowing the paver to rest flat and stable during cutting.

Making the cut

Position the porcelain paver on the cutting table of the manual tile cutter, aligning the marked cut line with the scoring wheel.

Hold the paver securely with one hand while using the other hand to guide the scoring wheel along the marked line. Apply steady, firm pressure to score the surface of the paver.

Move the scoring wheel along the entire length of the marked cut line in one continuous motion. Aim to create a visible and well-defined score line on the surface of the porcelain paver. Take care to ensure the score line is straight and accurate.

Once the porcelain paver is scored, reposition it on the cutting table, aligning the score line with the breaking mechanism of the manual tile cutter. Apply pressure evenly on both sides of the scored line, using the handle or pressure bar of the tile cutter.

Gradually increase the pressure while keeping the pressure points equidistant from the scored line. The pressure will cause the porcelain paver to break along the scored line, resulting in a clean and precise cut.

Apply enough pressure to snap the paver, but be cautious not to exert an excessive force that may cause the paver to break unevenly or chip.

Circular saw

A handheld circular saw is a versatile tool for making small, detailed cuts or intricate shapes in porcelain pavers. It requires some previous knowledge of working with masonry blades, so they are not recommended for beginners.

Preparation

The preparation follows basically the same steps as the angle grinder, including setting up a wet cut, so refer to that examples for the complete guideline.

Making the cut

Position the circular saw at the starting point of the marked cut line. Holding it firmly with a comfortable grip, using both hands for stability and control.

Apply steady and controlled pressure as you guide it along the marked line. Maintain a slow and deliberate pace, allowing the blade to gradually cut through the porcelain. Keep the blade aligned with the cut line to ensure precision.

Ask for professional help to cut porcelain pavers

As you could see, cutting porcelain pavers requires the right tools, techniques, and attention to detail. The process is not trivial.

By following the guidelines provided in this comprehensive guide, you will be well-equipped to cut porcelain pavers, but nothing substitutes the work a professional would be able to provide.

Porcelain pavers are maybe the best in the market at the moment, but they are fairly difficult to work with. That’s why we always recommend hiring professionals you can trust in your area to help you with your project.

Here at JS Brick, we have helped countless homeowners with their porcelain paver installation over our 23 years of experience in the industry, so we know firsthand how tricky things can get when working with porcelain pavers.

So if you happen to be around our area of activity – Sarasota County, in FL – we can gladly help you with your project.

Get in contact so we can start helping you today!